Fundamentals of Design

- tags: Machine Design MIT

- Resources

- Notes

-

Henry Maudslay’s Maxims (1700’s, a father of modern machine tools)

- Get a clear notion of what you desire to accomplish, then you will probably get it

- Keep a sharp look-out upon your materials: Get rid of every pound of material you can do without. Put yourself to the question, ‘What business has it there?’

- Avoid complexities and make everything as simple as possible

- Remember the get-ability of parts

- Engineering design problems are essentially cost and performance trade-offs, and a key element of performance is time to market. It does not matter how good your solution is if you miss the market window.

- Being able to create a first order solid model of the system with appropriate proportions is an invaluable skill. Designers should continually learn about proportions by looking at real world devices from bikes to construction equipment.

-

Deterministic Design

-

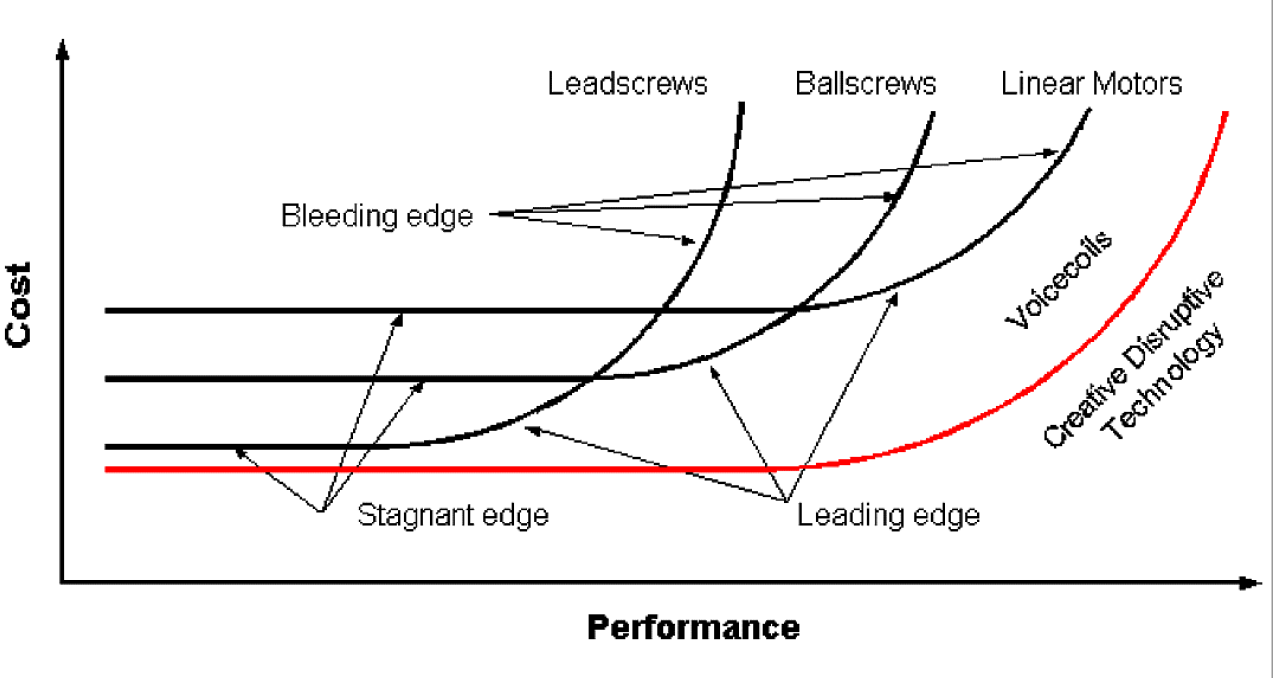

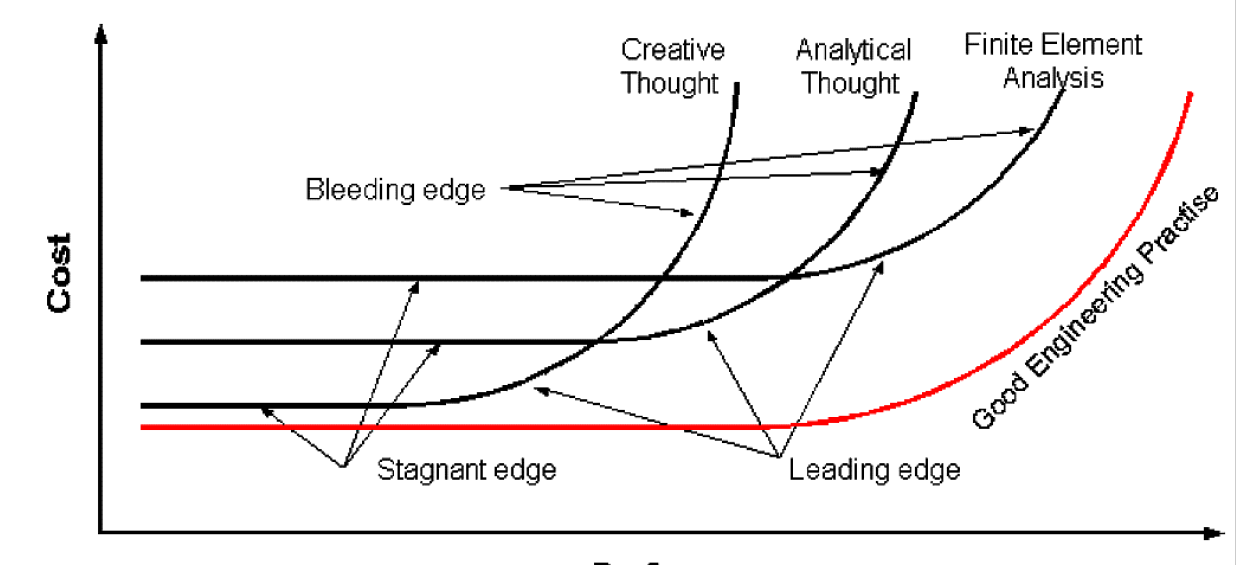

Everything has a cost, and everything performs to some degree.

- Extract all the performance you can get from the same cost.

-

Play with the design problem

- Playing with the problem and look at the available resources.

- Physically engage with the problem and possible solutions, create models in your mind and physically with simple methods, visualize and simulate in your head. Actively engage with random ideas.

- Sketching the problem and possible solutions is how we communicate with others and ourselves.

- Modelling problems and possible solution concepts allows to develop and evolve ideas.

- Analytical models can allow you to identify the most sensitive parameters of the problem and help guide your solution path. Enable you to optimize your solution to minimize cost and effort. Analytical models allow others to understand your intent.

- Detailing the solution before you build can help identify minute yet critical features that may otherwise cause failure: Bolt holes should be drawn so you can envision how the system will be assembled.

- “Personal self-satisfaction is the death of the scientist. Collective self-satisfaction is the death of the research. It is restlessness, anxiety, dissatisfaction, agony of the mind that nourish science” Jacques-Lucien Monod

-

Fundamental Principles

-

Occams Razor

- “The medieval rule of parsimony, or principle of economy, frequently used by Ockham came to be known as Ockham’s razor. The rule, which said that __plurality should not be assumed without necessity.__

- A problem should be stated in its most basic and simplest terms.

- The simplest theory that fits the facts of a problem is the one that should be selected.

- Limit Analysis can be used to check ideas.

- Complexity is to be minimized in both design and manufacturing.

- The first opportunity is to keep a simple design strategy, the second one is in the design concept stage where you reference previous designs are look at the simpler solutions. The third is in the formation of modules, module’s functional requirements come from the design parameters in the concept.

-

-

-

The fourth is to keep manufacturing in mind, in both design and selection of components. It is not always beneficial to reduce the number of components, it is critical to keep the functional requirements of the design in mind but also the implied functional requirements of the components and their operations. - Sometimes reducing the number of components leads to specification of a few highly complex components. Thus the goal is to minimize the number of components, and balance component complexity with the number and complexity of manufacturing processes and the quantity to be manufactured. In large quantities, such as in automotive applications, minimizing material mass and number of components often outweighs any perceived manufacturing complexity, because process machines and tooling are quickly amortized. - ### Newtons Laws - Newton’s First Law **sets the stage for the motion of objects: **__Every body persists in its state of rest or of uniform motion in a straight line unless it is compelled to change that state by forces imposed on it.__ This law is what we use when we say the sum of forces must be zero, and the sum of moments about a point must be zero: Force and moment equilibrium must exist. - Newton’s Second Law is a generalized version of the first law: __The acceleration of a body is directly proportional to the resultant force acting on it and parallel in direction to this force and that the acceleration, for a given force, is inversely proportional to the mass of the body. __The same is true for rotary motion systems where a force F is replaced by a torque Γ, mass m by moment of inertia J, and linear acceleration a by angular acceleration. - Newton’s Third Law states: To every action there is always opposed an equal reaction **or, the mutual actions of two bodies upon each other are always equal and directed to contrary parts. Newton’s third law **directly leads to the principle of conservation of linear and angular momentum: When the resultant external force acting on a system is zero, the total vector momentum of the system remains constant. This is true for both linear, P, and angular, L, momentum - ## Saint - Venants Principle - In 19th century using a new tool called calculus to solve the elastic behavior of solids, One problem that precludes finding rigiours solution to practical problem was the complexity caused by the desire to include every facet of a system in its model. - Like in finding the deflection of a cantilever beam, modelling the local deformation at the tip of the beam can make the problem difficult to solve. - In order to make analytical models more tractable, what is referred to as Saint-Venant’s principle is often applied, which states that several characteristic dimensions away from an effect, the effect is essentially dissipated. Saint-Venant demonstrated this by using a pair of pliers to squeeze a rubber bar, and the deformation and stress effects become very small 3-5 bar thicknesses away. - we can apply Maxwell’s reciprocity to Saint-Venant’s principal and observe that if an effect is to dominate a system, it must be applied over 3-5 characteristic dimensions of the system. - When mounting bearings to support a shaft, for example, the bearings should be spaced 3-5 shaft diameters apart if the bearings are to effectively resist moments applied to the shaft. In a machine tool structure, for example, if one is to minimize bending, the length of the structure should be no more than 3-5 times the depth of the beam. When bolting components together, in order to make the bolted joint act almost as if it were welded together, the bolts’ strain (stress) cones should overlap. - Consider the mounting of a wheel to a shaft that is to be held by bearings. The critical design parameters are the distance from the wheel to the first bearing, the distance between the first and second bearings, the diameter of the shaft, and the support structure and its loading.

In the first case, if the wheel is cantilevered out far from the first bearing, it can cause the bearing to be overloaded. The cantilever distance should be less than 2 shaft diameters in order to prevent angular deflections of the shaft from taking up all that is allowed for the front bearing which acts as a fulcrum.

Next, the shaft in the region between the first and second bearings acts as a lever. If the lever is made very long to minimize forces on the bearings, then there is the risk that it will deform too much and cause the bearings to overload.

In order for the second bearing to have dominance over the system, but not allow the shaft to bend too much, it should be at least 3-5 shaft diameters from the first bearing. If a larger spacing is desired, perhaps to reduce the number of components, then one must consider the effects of deformations of the structure surrounding the bearings.

Consider the case with a vehicle cross-section, if all the parts are sized and located correctly and analysis shows that the stresses appear to be within limits, but if the frame of the vehicle is compliant then a heavy load in the middle might cause the shaft to pivot in the bearings and take up all the radial clearance causing bearing failure. The only way to solve that is to either increase the rigidity of the frame or use two sets of bearings to distribute the force. - In steel and paper mills, the shafts are so long and heavily loaded, that the only way angular deflections can be accommodated is with the use of Sperical bearing