Flexure

- tags: Materials Mechanisms

- Resources

- Flexure notes Mat mit MIT

- Characteristics of Beam based flexures

-

Spherical Flextures

- Spherical flextures with tetrahedron joints

- Spherical Flextures Motion reduction, resolution enhancement.

- Precision Balls catalogue of Flextures learning

- Flexture encyloperdia precision balls learning

- Precision design Lab University of Michigan

- Amy Flexture lecture

- Principles for desigining Precision Machines MIT

- MIT paper Sara Design of educational Flextures #Dspace MIT

- Snap-Fits for Assembly & Disassembly by Tim Spahr (PDF)

- Snap-Fit Design Manual by BASF (PDF)

- Snap-Fit Joints for Plastics - A Design Guide by BAYER

- Additive assembly of digital materials by Jonathan Ward

- Digital materials for digital fabrication by George A. Popescu

- Customized digital manufacturing : concept to construction methods across varying product scales by Marcel Botha

- Design modeling and fabrication of experimental apparatus for compliant mechanism education kit by Sarah E. Shivers

- Integral Mechanical Attachment, 1st Edition by R. Messler (Pg 103 - 141)

- Origami like creases in sheet metal

- Links between origami and compliant mechanism

- Companies

- Flexures are bearings with limited range of motion, they have no backlash and last long with good material.

- As you make the flexure thinner, the center of rotation of the flexure is more defined, this help with calculations in micro Actuators Also when flexures are connected in parallel they tend to cancel out any parasitic motion and help define the center of rotation better.

- The seventh Degree of freedom

- conventional wisdom says that there are only six degrees of freedom, but that assumes that the constrained bodies are rigid. But there is no such thing as a rigid body.

The inevitable flexibility of all the structures is the seventh degree of freedom Elasticity isn’t really the seventh degree, the deflection caused by an applied force accounts for that degree of freedom.

Question is, if there are two vector forces on the body does that give it 8 degrees of freedom or will the forces combine to a resultant

- In the stress strain curve of a material, the slope of the curve in the elastic region is the Youngs modulus Which is the stiffness

- Compliant mechanism

-

Dan Gelbart

- In flextures, you can not only make a linear stage, but also reduction stages to couple the motion and provide leverage.

- The connecting pieces are called Wiggle bar they are effectively used to decouple the rotational motion of the frame from the linear motion.

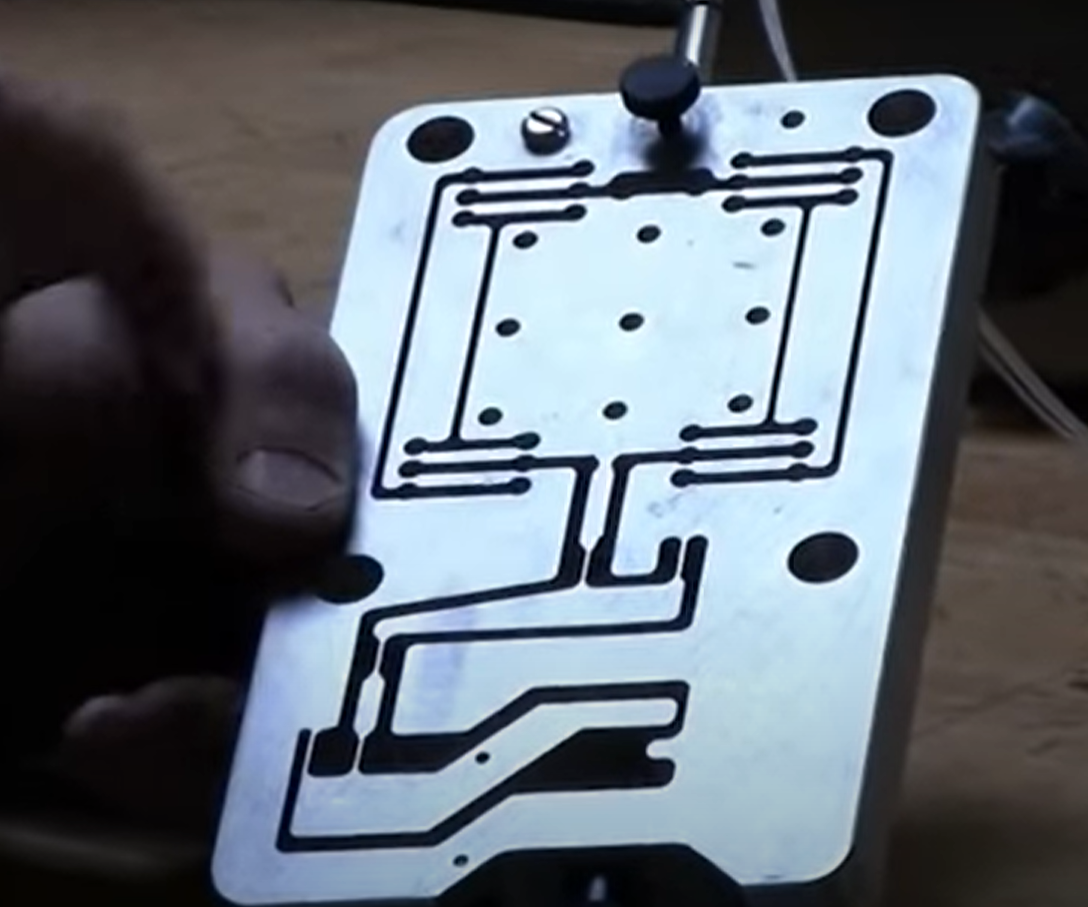

- If you want a high accruacy flexture, you need to pre-drill the holes because, how well this moves, how linear it is depends on the exact mataching of the pivot points. So drill and ream the holes, align on waterjet.

- Aluminum is used for prototyping but they are very temperature sensitive and cannot be used for fine positioning.

- Flextures are limited by the elastic range of the material, even in good steel, the elastic range is 1%, so for large travels its best to have Nitinol, which has an elastic range 10 times as much as steel.

- Flex pivots or cross hinge pivots it works over small angles.

- No need to lubricate, no wear, infinite life, no backlash.

- Infinite life can be achieved if you do not use up all the elastic range. Ideally about 2/3rd can be utilized.

-

Flexure

- Flexures are usually thin as we want to minimize the spring force for moving them. The thinner the cross-section is the more certain we can estimate the center of rotation.

- If you use a single flexure, the center of pivot may not be accurately determined. But if we use them in pairs then the instabilities tend to cancel themselves out.

- Plastic turning white because of loads is called crazing, keep creep in mind for static loads over long times.

-

tags: Flexure #Making Prototypes

- Flexure

Notes mentioning this note

Applied Robotic Stanford CS235

tags: Robotics #Making Prototypes Source CS235 Youtube What makes a good robot designer is the attention to the details. Every...

Compliant mechanism

tags: Machines CNC MTM Flexure Resources Flexible Research group UCLA Axiomatic design theory for systems Nam suh Quality through axiomatic...

Flexure

tags: Materials Mechanisms Resources Flexure notes Mat mit MIT Characteristics of Beam based flexures Spherical Flextures Spherical flextures with tetrahedron...

Machines

tags Machine Design Machines ZUND Digital cutting machine Roland MDX20 Small format precision milling machine. Omax Waterjet Machining center Abrasive...

Making Prototypes

tags: fab projects Rapid prototyping of prototyping machines Author: #Dan Gelbart Videos: Making prototypes watch learning Resources How to make...

Robotics

tags: Mechatronics Resources Machine learning for robot kinematics #Marginally clever CNC ROS for rest of us Joshua Awesome list of...

Soft Robotics

tags: Robotics Flexure

Resources

Harvard Whitesides Soft Robotics

Pneumatic Structures by Thomas Herzog

Inflatables cookbook by Ant farm