Compliant mechanism

- tags: Machines CNC MTM Flexure

- Resources

- Flexible Research group UCLA

- Axiomatic design theory for systems Nam suh

- Quality through axiomatic design Nam suh

- Compliant Mechanism by Larry Howell

- Thesis on Flextures Shorya Awtar learning

- Handbook of compliant mechanisms learning

- BAX EDM Home made edm, Flextures Flexure

- Amy Flexture demo board

- Flxsys Compliant mechanismsFlexure

- Compliant mechanism design Facts of Mech

- Monolithic Binary stiffness building blocks of mechanical digital machines

- Lamina Emergent stages BYU

- Compliant precision lathe

- Notes

- Spring Stiffness

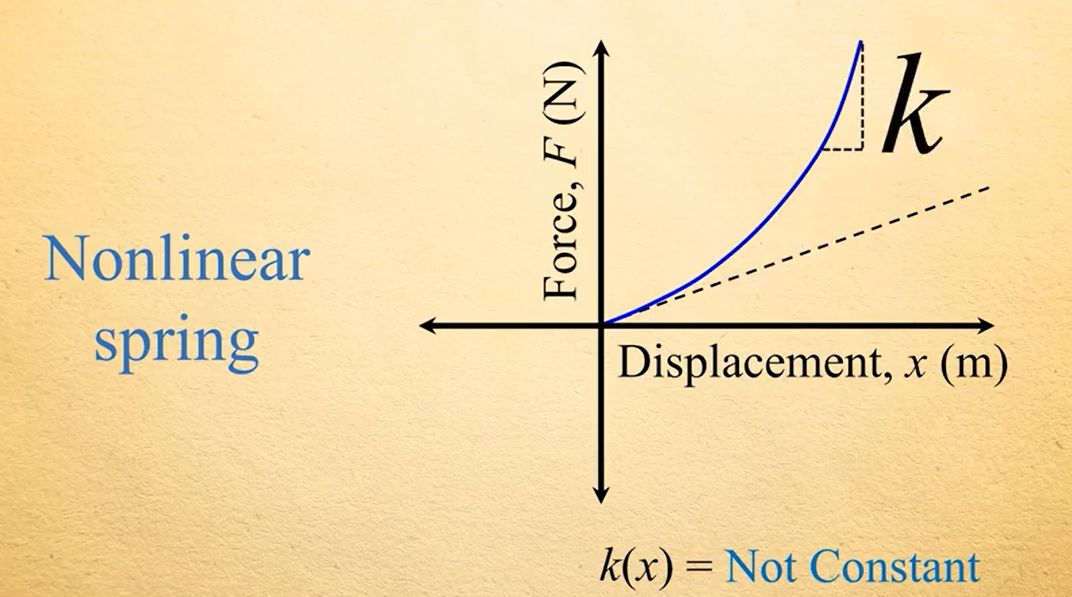

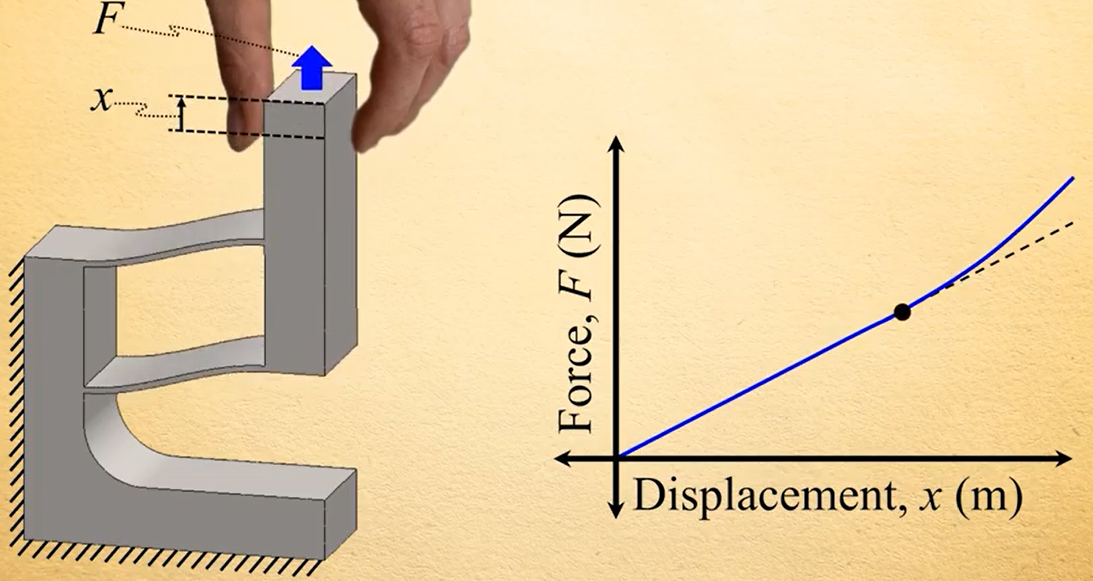

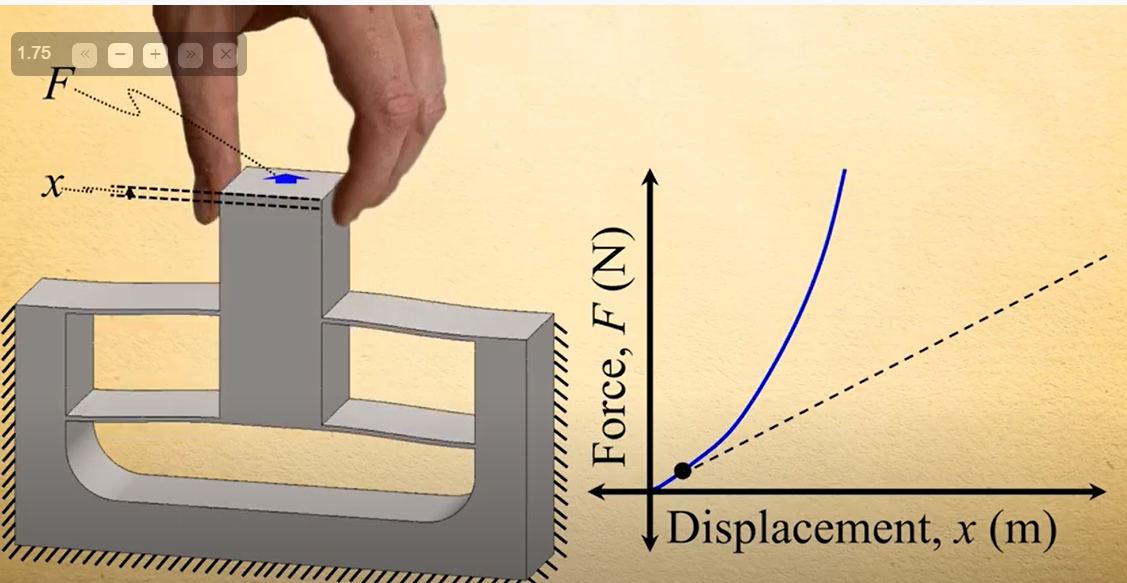

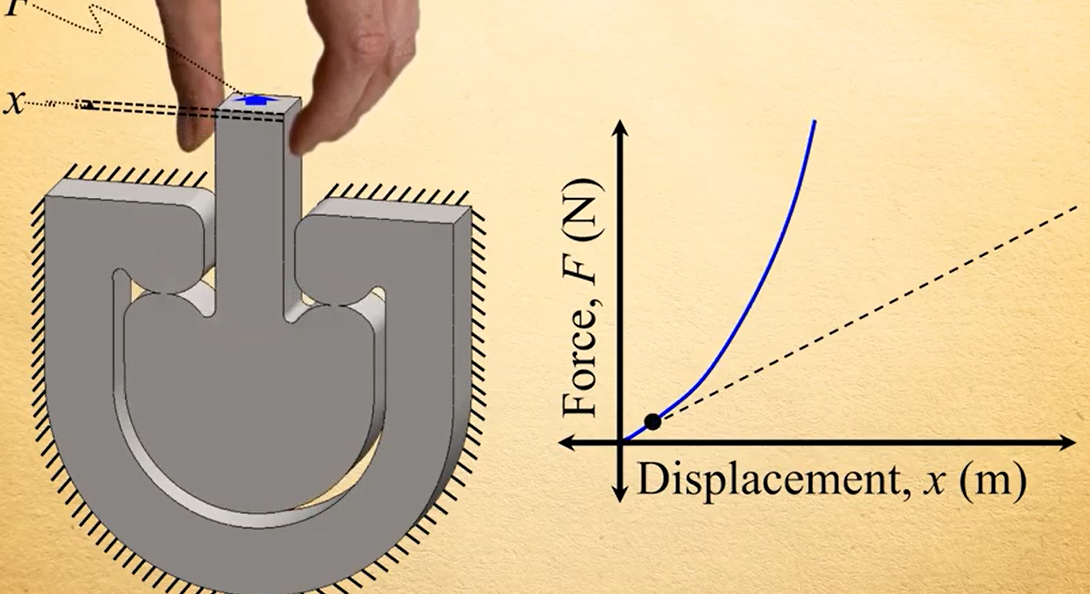

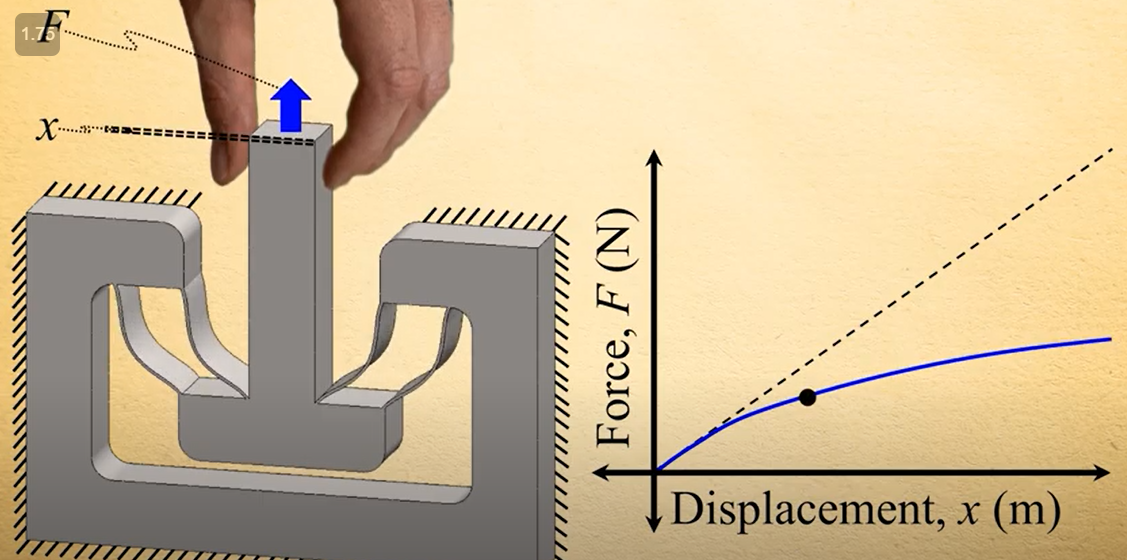

- Stiffness can be said as the derivate of the force with respect to the deflection. In a linear spring, this deflection will be a straight line.

- Ways to affect the stiffness,

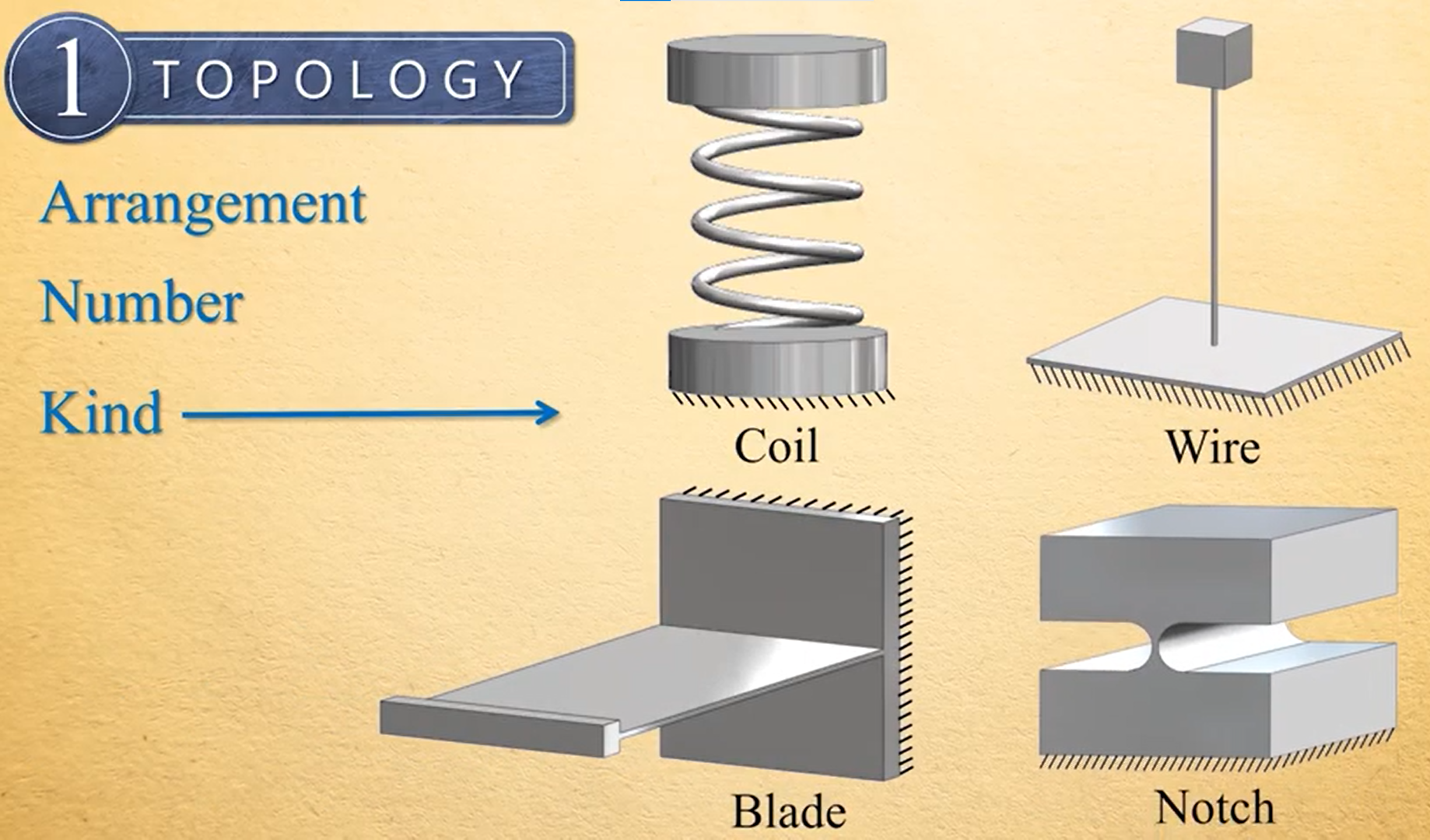

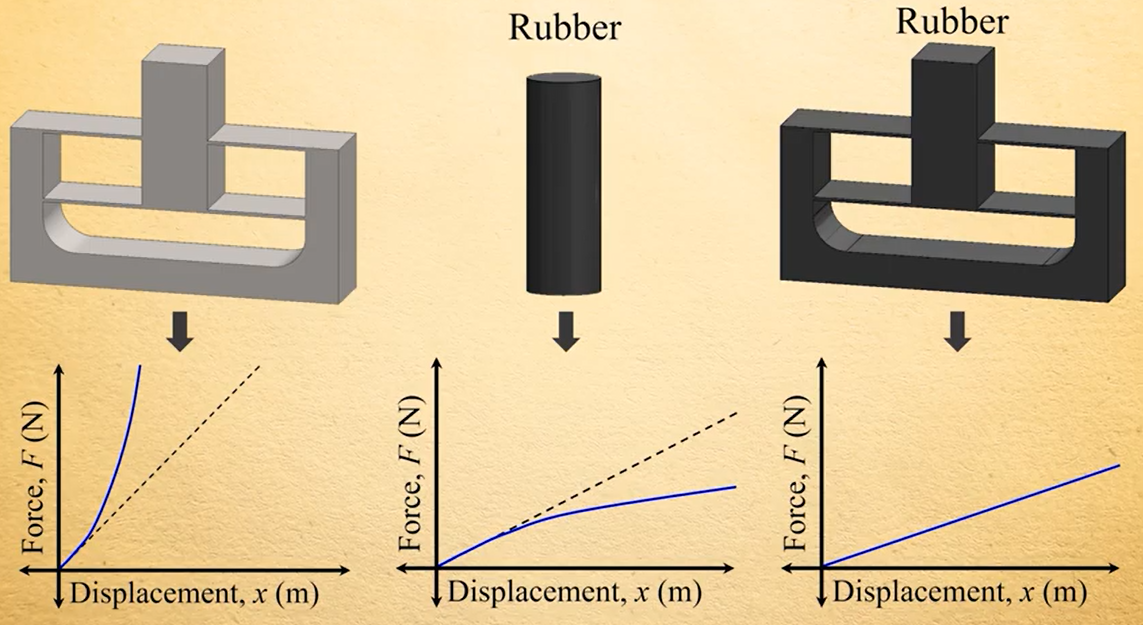

- Topology

- Geometry, making the blades thinner, longer and wider.

- Material, Making the spring out of more compliant materials.

- Topology

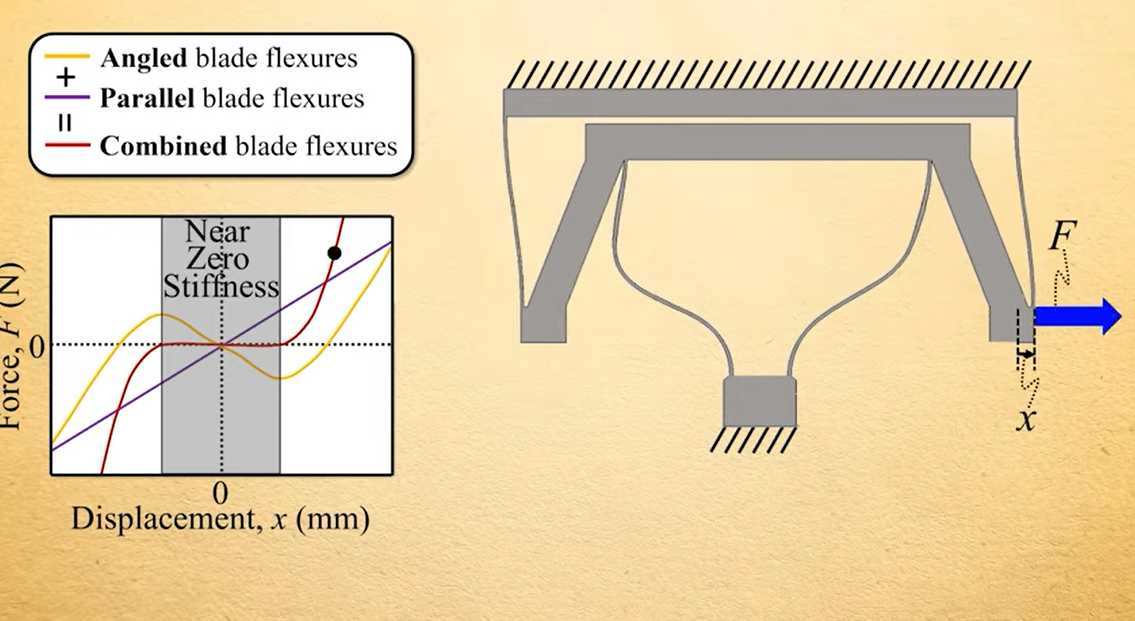

- Non linear springs

- Even though they can be considered linear, after certain deflection, the stiffness begins to increase appreciably.

- The stiffness changes almost immediately as the beams have to stretch and bend as they deform.

- Some springs can be designed to reduce the stiffness as they buckle.

- Most metals exhibit a linear stress strain relationship, but some elastomers have non linear elastic properties that change as the material is deformed. If we combine the stiffness properties of a design with a complementary material we can alter the design to have optimal stiffness along the range of motion.

- The nonlinear elastic properties of the spring are canceled by the nonlinear properties of the material.

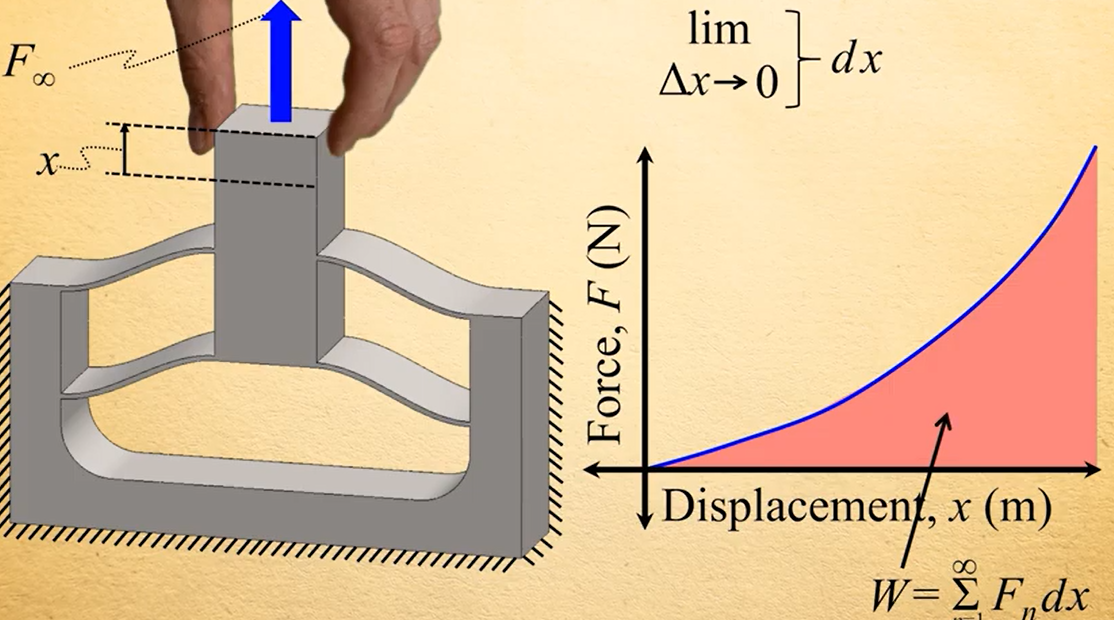

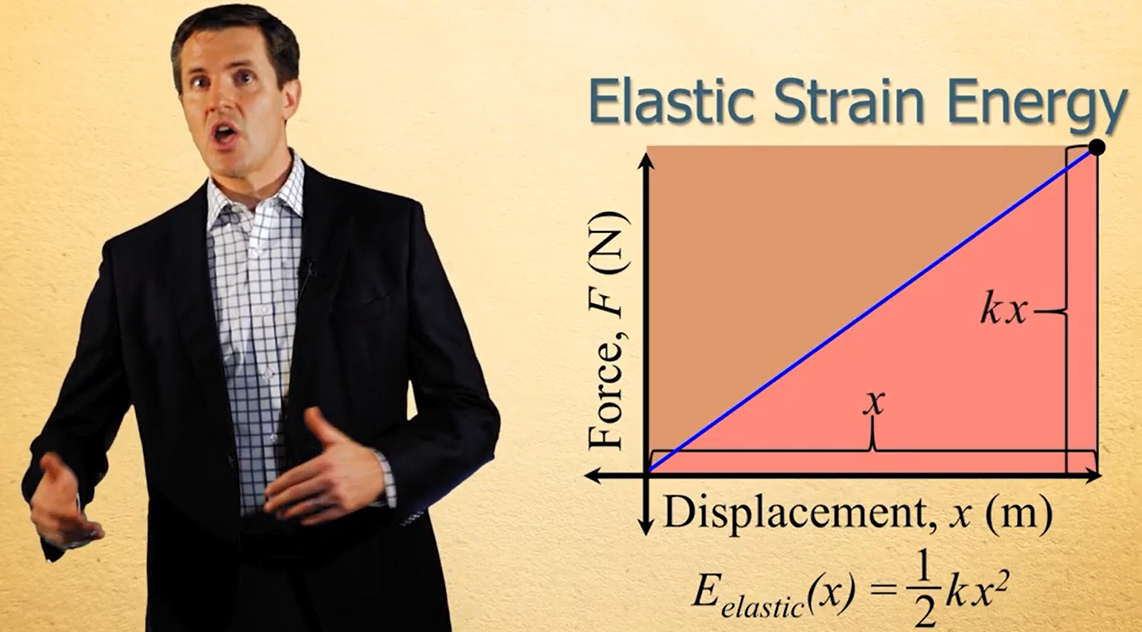

- Elastic strain Energy

- Under elastic conditions and given the material is not permanently damaged, all the work under the force displacement graph is said to be stored in spring as Elastic strain energy.

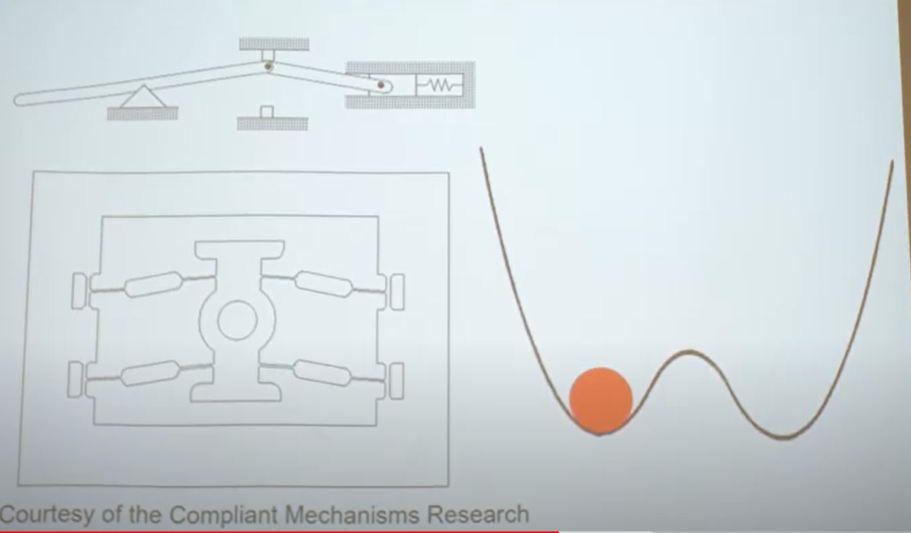

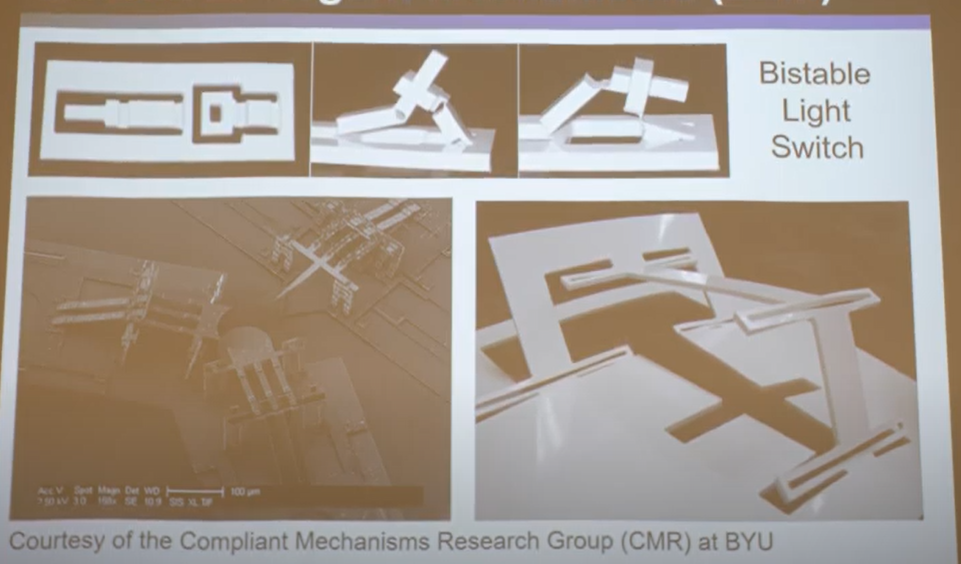

- Bi Stable switch

- The stiffness of the two elements can be added together because they are parallel, ie they experience the same displacement of the shuttle.

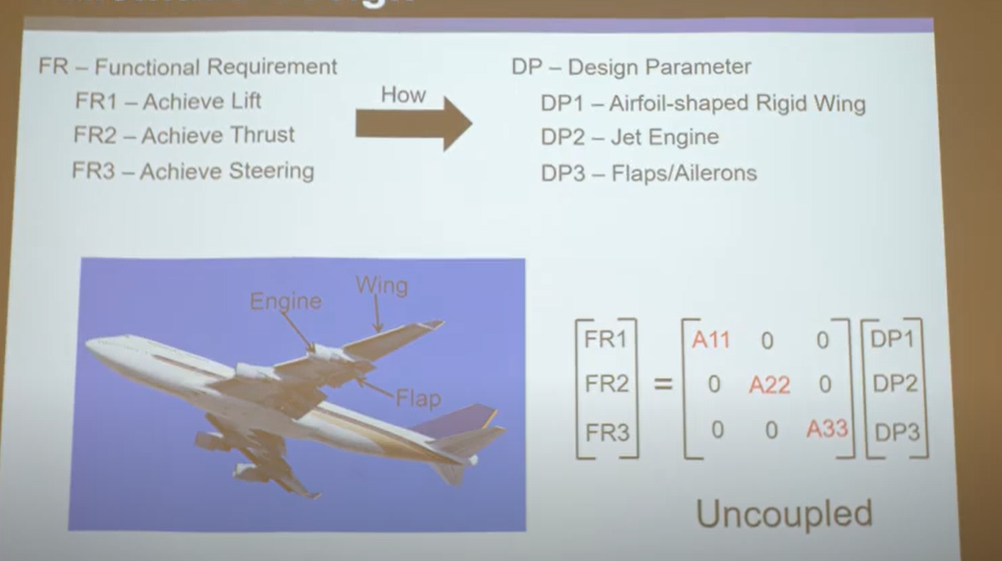

- Axiomatic design

- Functional parameter only affect one area of the design parameter and the requirements are uncoupled from the design parameters.

- Compliant systems are inherently nonlinear and optimizing for all the variables is difficult and time-consuming. In nature, all systems are coupled and influence one another.

- For eg, if we wanted a circular motion about an axis, its easier to use rigid bodies and put a pin joint there, if we were to make it compliant then it becomes a non linear problem where the center of rotation will depend on the force, location and the material.

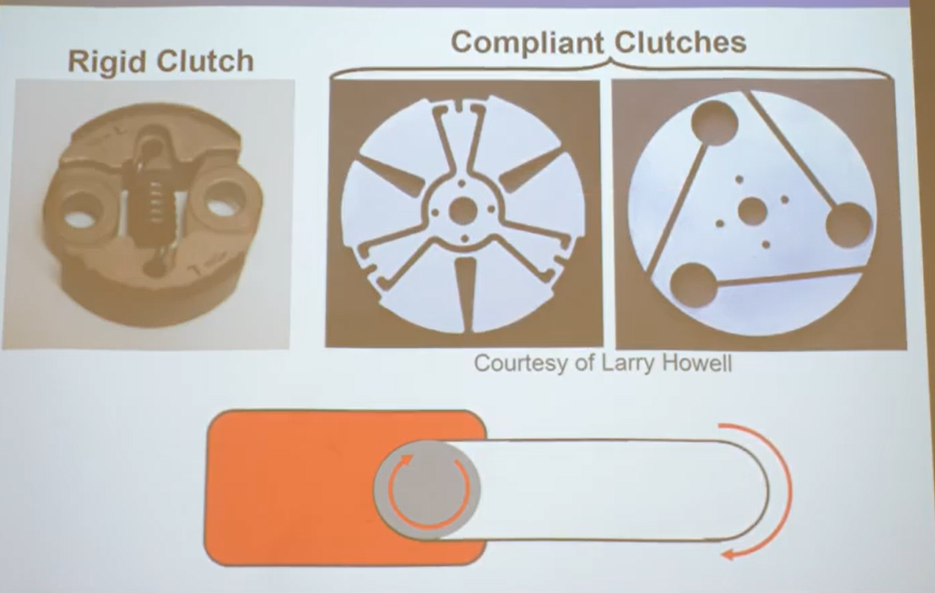

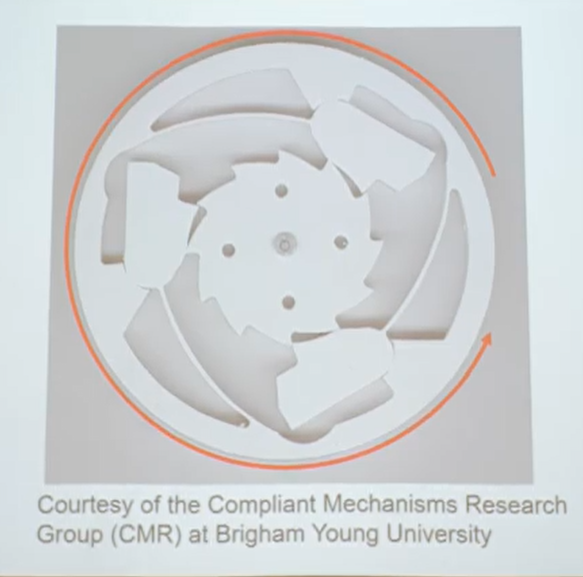

- Compliant clutches.

- 360 Robot joint

- These are rigidly constrained in all directions but offer zero stiffness in rotation. Used for robot joints. These can be taken a step further with engineered materials.

- Over running clutch

- Bi Stable Switch

- Lamina Emergent Systems

- Making things in 2D that can assemble on fold into 3D shapes.

-

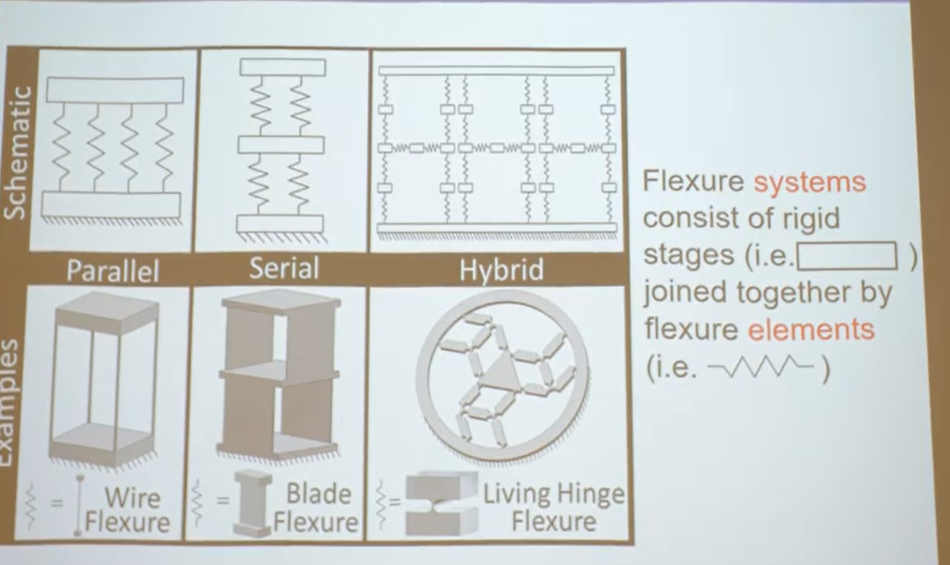

Flexure

- A flexure is a mechanism consisting of a series of rigid bodies connected together by compliant elements that is design to produce a geometrically defined motion upon application of force. - Stuart Smith

- Spring Stiffness

-

tags: #Mechanical #Compliant mechanism #Machine Design

- Compliant mechanism

Notes mentioning this note

Compliant mechanism

tags: Machines CNC MTM Flexure Resources Flexible Research group UCLA Axiomatic design theory for systems Nam suh Quality through axiomatic...

Flexure

tags: Materials Mechanisms Resources Flexure notes Mat mit MIT Characteristics of Beam based flexures Spherical Flextures Spherical flextures with tetrahedron...

Machine Design

tags: Robotics #Mechanical Machines Fabable Machines Linkages Resources Theory Basic Machines US Navy guide to basic machines like levers, gears....